Brake Fluids: A Complete Guide

Have you ever been shopping for brake fluids, looking at different brake fluids, and trying to figure out which one is best for your vehicle? Or perhaps you simply want your braking or clutch system to work at its best? Is it the price or the fancy label on the bottle that influences your decision? There are numerous possibilities and a great deal of information to go through.

To understand which brake fluids will be best suitable for your vehicle, you would need to understand how brakes, in general, work.

How Does A Braking System Work?

https://www.flickr.com/photos/simonov/49020917061

A braking system is designed to control and stop any moving machinery. To do so, various components within the braking system must convert the moving object’s kinetic energy into thermal energy. This force conversion is carried out by friction, which reduces the vehicle’s speed and aids in de-acceleration.

Although other methods of converting the energy can be used, most brakes use friction between two surfaces that are compressed to convert the kinetic energy of the moving object into thermal energy. Regenerative braking, for example, converts a large portion of the energy into electrical energy that can be stored for later use.

The frictional force is generated by the contact of bodies between the shoe and the moving drum or disc of an automobile braking system. Friction causes the production of heat, which in turn causes components such as pads, liners, drums, and discs to become heated, slowing down the moving body.

The surface nature of the materials determines the frictional force, and the speed of relative motion is used to achieve the braking effect of a moving body. As a result, the bodies need to be pressed tighter together to generate more friction. The faster the respective bodies move in correspondence to each other, the more friction they would produce, hence slowing down the vehicle.

Design and Basics

While most cars and trucks on the road today have four-wheel disc brakes, some older cars and trucks still have drum brakes. Drum brakes include a hollow cylinder (the drum) linked to the axle that spins with the wheel and is typically used on the back wheels.

When you apply the brakes, brake shoes contact the inside of the drum rather than the outside of the rotor. Drum brakes can deliver more braking force than corresponding size disc brakes. They also endure longer and are less expensive to produce. On the other hand, drum brakes are more difficult to service since they are heavy, take a long time to dry, and can overheat quickly. Most modern automobiles now feature disc brakes as standard equipment.

The Importance of Brake Fluid

Brake fluid is essential to the correct operation of your vehicle’s brake system. The brake fluid facilitates the movement of the brake system’s numerous components by working at extremely high temperatures. Brake fluid is a non-compressible material found within the brake lines that supply the force generated when the brake pedal is pressed. This force is applied to each of the vehicle’s four brake rotors, thereby exerting pressure on the wheels to slow or halt the vehicle’s movement.

Brake fluids are mostly utilized in on- and off-road vehicles’ braking and clutch systems. Automobiles, motorbikes, and light trucks are examples of typical applications. The braking system is critical for driving safety, with nearly 253 million automobiles on American roads every day.

While auto owners may replace brake pads, rotors, or drums based on a mechanic’s recommendation or maybe because their car isn’t stopping as quickly as it used to, few individuals replace their brake fluid. Brake fluid is, without a doubt, a car’s most overlooked component.

Oil, transmission, coolant, and differential fluid changes are just a few of the time-based or mileage-based services that should be performed, according to your vehicle’s manual. On the other hand, most American manuals include no recommendations for when to change the brake fluid. Fluid manufacturers’ and other countries’ recommendations for flushing the brake system normally range from one to two years.

Brake fluid is necessary for a variety of reasons, including protecting the metals utilized inside components such as braking calipers, ABS control valves, and cylinders.

When to Replace Brake Fluid

https://pxhere.com/en/photo/1217636

Why and when should you change your brake fluid? Simply put, brake fluid should be replenished just like the other fluids in your vehicle. It gets contaminated by hoses and lines that have deteriorated. Mostly moisture contamination occurs when the master cylinder is opened to inspect the fluid level.

This is the one vital component of your vehicle that you may overlook. Many people are unaware that it exists until it is too late!

Your braking system is a component of your car. The fluid in your brakes, like any other component, needs to be checked and maintained on a regular basis. How often do you need to change your brake fluid? This is a question that many people have.

Your automobile will run and brake safely if your brakes are checked and maintained on a timely basis. A braking system in need of a brake fluid replacement might lead to a brake system failure and enhance your chances of being involved in an accident.

Air contamination will stay in the system if the brakes are not properly bled. Brake-related high temperatures can potentially fry the oil inside the caliper or wheel cylinder. When this heat is paired with any of the pollutants described previously, the braking system can work poorly.

The following contaminations affect a vehicle’s brakes. Read on to find out how to protect your vehicle from these contaminants so you can brake smoothly.

Air

Air contamination can arise in a braking system in a number of ways. Poor systemic bleeding is the most common cause. Air may also enter the system through worn-out seals and components. The seals will break down over time as the pistons move back and forth, allowing air into the system. When old or broken components are replaced, air pockets may enter the system, making purging difficult.

The typical air removal procedure of having one person push the brake pedal while another sucks the air out at the wheel can take a long time and isn’t always efficient in eliminating all of the air. For eliminating air, vacuum and pressure systems are superior solutions.

Moisture

Brake fluid is manufactured to absorb moisture. Water molecules will corrode the interior components and ruin the braking system if the fluid does not absorb these molecules. Of course, there is a cost associated with this trait. The performance of braking fluid degrades as moisture is absorbed. High temperatures, typical in braking systems, can cause moisture to evaporate, causing the fluid to become compressible and give you that “spongy” feeling.

Not all brake fluids have this moisture-absorbing capability. Silicone fluids can only absorb a certain amount of moisture before remaining in free form and sinking too low points in the system. This may result in rusting.

Burning Smell

If you hear weird noises during braking, it could be due to a lack of brake fluid or another problem with the brake system. Scraping or grinding noises are common sounds.

Burning odors following strong braking could indicate that your brake fluid has been burned out. In this instance, you should pull over to a safe location and allow your car to cool down. You should also seek advice from a local mechanic and plan a servicing visit. Driving with burned brake fluid can lead to more catastrophic problems, such as brake failure.

Classifications and Standards

The United States Department of Transportation (DOT) divides brake fluids into four categories: DOT 3, DOT 4, DOT 5, and DOT 5.1. The majority of fluids are classified as DOT 3, DOT 4, or DOT 5.1. These fluids are hygroscopic, which means they absorb water from the air. Although DOT 5 fluids are not hygroscopic, they are frequently utilized in vehicles that sit for extended periods of time, such as collector cars and military vehicles.

The chemical composition of fluids varies depending on the classification. Glycol ether-based fluids are used in DOT 3. Glycol ether and borate ester are combined in DOT 4 fluids. DOT 5.1 fluids contain borate ester with a little amount of glycol ether, whereas DOT 5 fluids are silicone-based.

The Federal Motor Vehicle Safety Standards (FMVSS) No. 116 specifies the attributes that a brake fluid must possess in order to be classified by the Department of Transportation (DOT).

These characteristics have an impact on how a brake fluid functions. The boiling point is one of the most important markers of how the braking or clutch system will behave. The friction from the brake pads coming into touch with the drum or disc causes wheel cylinders and brake calipers to reach extremely high temperatures during braking. Caliper temperatures of 400 to 500 degrees F are not uncommon during road course events and track days.

The brake fluid must still function at these higher-than-normal temperatures. Inside the line, a fluid that has reached its boiling point will evaporate. As a result, the fluid becomes compressible, resulting in insufficient hydraulic braking force transfer.

There are two types of boiling points, Dry and Wet boiling points. The dry boiling point of a fluid is the temperature at which it boils when it is removed from its container. Based on 3.7 percent water absorption, the wet boiling point is calculated.

The viscosity of the braking fluid is another important characteristic. Fluids must fulfill SAE requirements at minus 40 degrees C and 100 degrees C. The minimum and maximum viscosity ranges will differ depending on the categorization.

Brake fluids must maintain low compressibility even when temperatures change in various climatic conditions. This is necessary to maintain a consistent brake pedal feel. More brake pedal travel is required for the same amount of brake caliper piston force as compressibility increases.

The following table illustrates the differences in the categories of Brake fluids:

|

Category |

Dry boiling point |

Wet boiling point |

Viscosity at -40 °C°F |

Viscosity at 100 °C (212 °F) |

chemical composition |

|

DOT 2 |

190 °C (374 °F) |

140 °C (284 °F) |

– |

– |

Castor Oil/Alcohol |

|

DOT 3 |

205 °C (401 °F) |

140 °C (284 °F) |

Max. 1500 mm2/s |

Min. 1.5 mm2/s |

Glycol Ether |

|

DOT 4 |

230 °C (446 °F) |

155 °C (311 °F) |

Max. 1,800 mm2/s |

Min. 1.5 mm2/s |

Glycol Ether/Borate Ester |

|

DOT 4+, Super DOT 4 |

230 °C (446 °F) |

155 °C (311 °F) |

Max. 750 mm2/s |

Min. 1.5 mm2/s |

Glycol Ether/Borate Ester |

|

DOT 5 |

260 °C (500 °F) |

180 °C (356 °F) |

Max. 900 mm2/s |

Min. 1.5 mm2/s |

Silicone |

|

DOT 5.1 |

260 °C (500 °F) |

180 °C (356 °F) |

Max. 900 mm2/s |

Min. 1.5 mm2/s |

Glycol Ether/Borate Ester |

|

LHM |

249 °C (480 °F) |

249 °C (480 °F) |

Max. 1,000-1,200 mm2/s |

6-6.5 mm2/s |

Mineral Oil |

DOT 2

DOT 2 fluid is mineral oil-based, mainly Castor Oil or Alcohol, and has extremely low wet and dry boiling temperatures. It is not commonly utilized in the automotive industry. In fact, the dry boiling point of DOT 2 is the same as the wet boiling point of DOT 5 and 5.1. Since it has a very low boiling point and absorbs a lot of moisture from the air, its life is the shortest among all types of brake fluids.

DOT 3

The most prevalent type of braking fluid used by everyday drivers is DOT 3. You can expect to find this type in most automobiles and trucks. DOT 3 has a boiling point of 401 degrees Fahrenheit when new and 284 degrees Fahrenheit when totally exhausted. This increases the likelihood of your brake fluid boiling. Exhaustion of the fluid can be sped up by braking forcefully, going downhill for a long time, pulling, or racing.

As DOT 3 is highly corrosive, extreme caution is advised. It will remove paint and should be wiped off with soap and water or a mild degreaser as soon as possible.

DOT 4

DOT 4 is predominantly utilized by European automobile manufacturers, but it is becoming increasingly common among automotive manufacturers worldwide. DOT 4 brake fluid has a greater boiling point than DOT 3 brake fluid, despite the fact that there are different varieties. The boiling point of these substances begins at 446 degrees Fahrenheit. DOT 4 contains additional chemicals that help decrease the acids that can build up due to moisture.

While it is technically possible to mix DOT 3 and 4, it is not recommended. DOT 4 is twice as expensive as DOT 3, and most people will see little gain from converting. There are various sorts of DOT 4, so be sure you’re using the right one. DOT 4 is mostly used by racers as it has a higher boiling point than DOT 3.

Some European and domestic automobiles employ DOT 4. Mercedes and Volvo both employ DOT 4 Plus. Some BMW cars use DOT 4 Low Viscosity. Finally, DOT 4 racing frequently has a blue hue added to it.

DOT 5

DOT 5 braking fluid is a silicone-based (Polydimethylsiloxane) corrosion protection and lubrication fluid designed specifically for use in hydraulic brake systems. The bluish-purplish tint of DOT 5 Silicone Brake Fluid makes it easy to spot. DOT 5 Brake Fluid has stronger thermal stability and higher dry and wet boiling points than DOT 3 and DOT 4 Brake Fluids. DOT 5 is also hydrophobic, meaning it won’t absorb water because it’s silicone-based.

DOT 5 cannot be mixed with any other fluid and is 4x more expensive than DOT 3. It is also compatible with a wide range of brake materials such as SBR, EP, Neoprene, and natural rubber.

DOT 5.1

Due to the lack of adoption of silicone-based fluids, DOT 5.1 was developed, a fluid that combines the performance benefits of silicone with the familiarity and compatibility of glycol ether fluids.

The DOT 5.1 has a boiling point similar to that of DOT 4 racing brake fluids. The color ranges from clear to amber. It is technically possible to blend it with DOT 3 or 4, but not advised. The cost of DOT 5.1 is almost 14 times that of DOT 3.

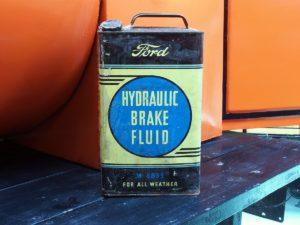

Packaging

https://commons.wikimedia.org/wiki/File:Ford_Hydraulic_Brake_Fluid_M_3833_for_all_wather_pic1.JG

Brake fluid should be kept in its original container in a clean, dry place at or below room temperature, preferably away from any petroleum products or fluid materials used for maintenance.

Always use the original package, which should be clearly marked and tightly sealed to avoid water absorption. New, unopened brake fluid containers with their foil seal intact will have a long shelf life in good storage conditions.

It’s also crucial to consider the packing in which brake fluid is shipped and stored. Always check to see if the foil cap is intact before purchase. Moisture contamination might occur if the bottle or lid is damaged. FMVSS No. 116 establishes packaging and labeling rules that all manufacturers must follow.

Instead of buying a larger bottle just because it’s a better value for money, but only the amount of brake fluid you actually require. Any remaining fluid should be discarded once it has been opened, as any humidity will be absorbed into the fluid and degrade the braking system’s function if you top-off or refill the system with the remaining fluid.

Testing Brake Fluids

The motor vehicle braking fluids standards are outlined in the Federal Motor Vehicle Safety Standards (FMVSS) No. 116. The brake fluid must pass the following tests to be considered for one of the DOT classifications:

- The boiling point of equilibrium reflux (dry boiling point)

- The boiling point of wet equilibrium reflux (tested with 3.7 percent water)

- Viscosities kinematics

- The pH level

- Fluid stability of the brakes (high-temperature and chemical stability)

- Corrosion

- Low-temperature fluidity and appearance

- Reserved

- Tolerance to water (low temperature and at 60 degrees C)

- Ease of Use (low temperature and at 60 degrees C)

- Oxidation resistance

- Cups and their effects

- Striking qualities

- Fluid color

Conclusion

When it comes to choosing brake fluid, the best suggestion is to stay with what you already use for your vehicle. Just because a fluid falls into a specific classification doesn’t mean it won’t perform as well as a fluid with a higher classification.

DEPENDING ON ITS COMPOSITION, a DOT 3 fluid may have a higher boiling point than a DOT 4 fluid. Furthermore, vehicles equipped with an anti-lock braking system (ABS) are meant to operate within the specified classification’s viscosity range.

It’s important to remember that, while all DOT-approved fluids are compatible, mixing them is not encouraged. Fluids classified as DOT 5 should never be combined with fluids classified in other categories. Different boiling points and standards can cause performance to suffer. The chemical composition of a DOT 3 fluid was devised and tested for compatibility with a vehicle that was specified to utilize it.

The chemical composition will change as classifications change, and the compatibility of components will be unknown. As a result, thorough system cleanses should be conducted while switching fluids.

As brake fluid absorbs moisture from the air and degrades over time, it must be drained and replaced on a regular basis. Brake fluid should be changed at the appropriate intervals to ensure good brake system operation. Brake fluid should be changed every one to two years, although different cars have varied recommendations for optimal performance.

As your vehicle’s brake system and brake fluid are fundamental to its safe operation, this service is critical. A certified professional vehicle technician should also perform this service.

A change in the brake fluid will largely go unnoticed unless you’re a skilled racing driver. It’s more crucial to bleed and seal your system when refilling your fluid properly. Also, brake fluid that has been sitting for a long time should not be used. As previously stated, braking fluids are hygroscopic, meaning that any moisture will end up within the bottle. You should be able to get many years of reliable braking by changing your brake fluid every one to two years.